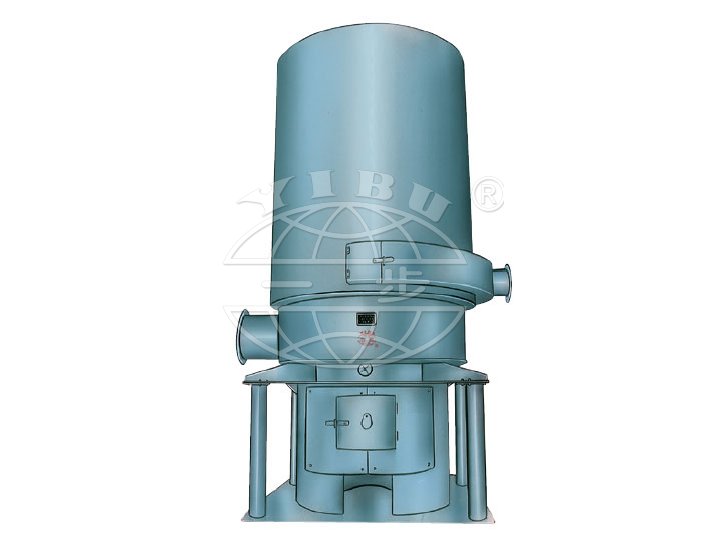

WNG Sereis Hot Pump Dryer

WNG Sereis Hot Pump Dryer

Description

Drying, as an ancient process technology, has been widely used in various fields of social production and living. While at the same time, drying consumes lots of energy. According to statistics, the energy dissipations of drying accounts for 7% ~ 15% of total energy consumption, while the thermal efficiency is only 25% ~ 50%, and most drying process has effects on the material’s color, nutrition, flavor and ingredients , especially on heat-sensitive materials (such as food and biological materials).

The advantage for the hot pump drying technology as bellow: small energy consumption, less pollution to the environment, good quality of dried product, wide usage and so on.Its excellent energy saving efficiency has been proved by various test institutes at home and abroad.

Application

It is widely used in low temperature drying and dehumidifying process in the following fields: subsidiary agricultural products, dehydrated vegetables, feed, medicinal herbs, seafood, electronic products, military products, such as jujube, mushrooms, pistachios, walnuts, raisins, honeysuckle, bacon, sausage, kelp, sweet potatoes, squash, chrysanthemum, Chinese wolfberry, etc

Principle

Heat pump working medium is compressed by compressor and becomes air with high temperature and high pressure, then it enters the condenser, condensates to liquid and releases heat to heat the air in the dryer and achieve the aim of improving the temperature of the dryer .meanwhile,the moisture of materials may evaporate in the hot air, and the water vapor would be discharged by the dehumidification system so as to achieve the purpose of drying materials.

Dehumidification system has hot air recycling device, and the recycled hot air can also be used to heat air, which may save 60% - 70% of the energy consumption.

Features

● Easy to install: It is convenient to install and remove, and it covers a small area, can be installed inside and outside.

● Efficient heat recovery: The heat recovery efficiency gets more than 60%, compared with the one of coal, oil, gas, water heater, nearly 75% operation cost can be saved.

● Safety and pollution-free: There is no combustion and emissions in the operation and it runs safely and reliably, is a kind of environmental friendly Equipment.

● Highly automatic and intelligent : It adopts automatic constant temperature device and can continuously work for 24 hours

Process flow diagram

- 2024-06-08 > Exhibition Invitation |ACHEMA 2024, Germany

- 2019-06-15 > P-MECH CHINA 2019 YIBU BOOTH NO: N3B10a

- 2019-04-15 > YIBU will attend the 57th CIPM Exhibition held in Changsha in Hunan province

- 2018-12-28 > Actived carbon particle mesh belt dryer made for Ingrevity

- 2018-03-10 > big spin flash dryer and spray dryer delivery to pakistan and Italy customer on time

- 2017-12-29 > two sets high speed centrifugal spray dryers and three sets of drum dryre delivered to Indonesia

- 2017-08-24 > one set of LPG-100 spray dryer is delivered to America

- 2017-08-24 > Five layers mesh belt dryer is sucessfully delivered to Manila(Philippines)

- 2017-04-05 > Exhibition interpack 2017 in Dusseldorf In Germany

- 2016-11-23 > The 18th International Exhibition in Moscow