PYG Series Pressure Spray Dryer With Top Air Outlet

Keywords:

Category: Spray dryer

Working principle The liquid feeding can be solvent, suspension liquid or emulsions. The material is fed into the atomizer inside the XX distributor which located in the top tower through the high pressure pump.The liquid is …

Detail Picture

PYG Series Pressure Spray Dryer With Top Air Outlet

Working principle

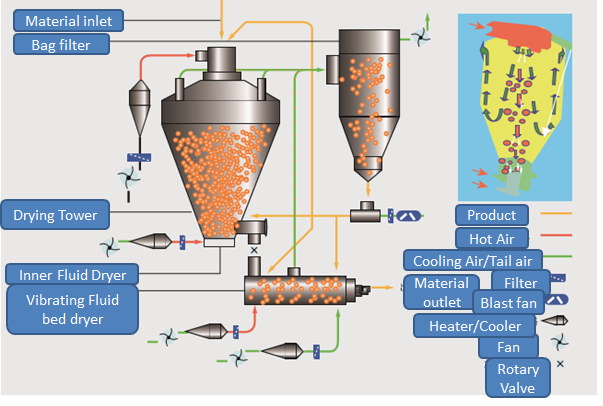

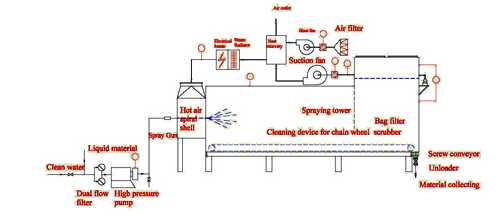

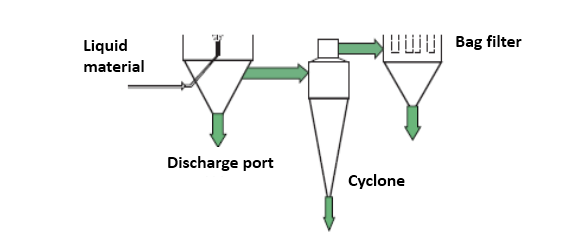

The liquid feeding can be solvent, suspension liquid or emulsions. The material is fed into the atomizer inside the XX distributor which located in the top tower through the high pressure pump.- The liquid is atomized by the pressure spray gun and then enters the dry air flow. and the air flow will carry the atomized droplets toward the inserted fluidized bed by the air flow , during this period ,the material is dried .

- While the particle enters the fluid bed dryer, the air will make opposite direction movements upward and exhausted from the top of the drying tower.

- The Ultrafine particles Separated from the exhaust air are recycle l to the drying tower.

- The particle fluidization in the fluid bed ,the fine circulation and the particle movements inside the dry air take place in an air environment whose dust density is higher than the one of traditional drying system. This design can overcome the sticky problem on the surface of the particles, and the particles with high moisture content can be processed.

- The water content of the particle entering the fluid bed can be controlled within the certain range .in this way ,it can obtain big particle and structure change(agglomeration and granulating).

- If necessary, the final drying and cooling of the material can be carried at the outside fluid bed dryer which connecting with the outlet of the inserted fluid bed dryer.

1.There is large adjusting range in particle size and moisture content of finished product;

2.Total height of the equipment is lower than the one of the concurrent spray tower;

3.Save energy, because the air –returnt chamber with top air outlet evaporate at the high negative pressure area of the upper section of the tower , it can low the evaporating temperature .it not only saves the heatsource ,but also saves energy.

4.The quality of the product is good, the particle size is uniform, and the adjusted range for the particle size is wide. the lustre and solubility of the particle is better .

Application:

Foodstuff: coffee,milk product, egg product, condiments, maltodextrin, soup, vegetable protein, yeast, etc

Chemical industry: detergent , dyes, fertilizers, inorganic salt, pesticides,

None...

None...

Next: None

News

- 2024-06-08 > Exhibition Invitation |ACHEMA 2024, Germany

- 2019-06-15 > P-MECH CHINA 2019 YIBU BOOTH NO: N3B10a

- 2019-04-15 > YIBU will attend the 57th CIPM Exhibition held in Changsha in Hunan province

- 2018-12-28 > Actived carbon particle mesh belt dryer made for Ingrevity

- 2018-03-10 > big spin flash dryer and spray dryer delivery to pakistan and Italy customer on time

- 2017-12-29 > two sets high speed centrifugal spray dryers and three sets of drum dryre delivered to Indonesia

- 2017-08-24 > one set of LPG-100 spray dryer is delivered to America

- 2017-08-24 > Five layers mesh belt dryer is sucessfully delivered to Manila(Philippines)

- 2017-04-05 > Exhibition interpack 2017 in Dusseldorf In Germany

- 2016-11-23 > The 18th International Exhibition in Moscow

Products