GZG Series Tube Bundle Dryer (Pipe Bundle Dryer)

GZG Series Tube Bundle Dryer (Pipe Bundle Dryer)

Description

The Tube Bundle Dryer is based on the conduction mode for drying.

The product to be heated and dried only contacts steam heated tubes,

and not directly steam. Tube bundles are operated on the counter-flow

principle (i. e. steam flows in the direction opposite t0 the direction of the material flow). The Tube Bundle Dryers are designed by considering the wet and dry product flow characteristics, lump crust formation tendency and thermal sensitivity of the material in dry condition.

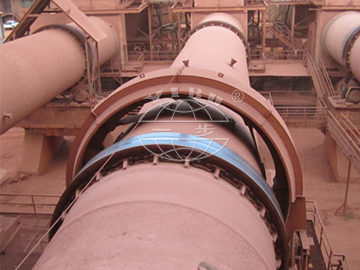

In the Tube bundle Dryer the tubes are arranged in a circumferential

manner on the inner periphery of the rotating shell. This entire shell and tubes assembly is supported on tyres / rollers & driven throughsuitable gear drive. Wet feed material is fed through material inlet nozzle installed at one end of the shell of dryer. This wet feed is fed through Screw Feeder. Feed material showered on the tubes with the help of lifting blades which are mounted on the rotating shell. Steam enters in the tubes through rotating joint installed at material discharge end of the shell. Material gets dried & discharged from the material discharge ports on the shell. Vapours are removed from the feed end with the help of suction blower after separating fines in the cyclone separator. The suitable sealing arrangement is provided to prevent air leakage and product \losses.

The Bundle Dryer the Tube Bundle is rotated inside the stationary

insulated housing. Steam is passed though one end of Tube Bundle for drying and condensate is removed from the other end.Wet feed Material to be dried is fed into the stationary dryer housing from Feed Nozzle at one end. The material gets lifted up & showered on tubes with the help of lifting blades provided on tube bundle periphery. Material gets dried by conduction heat transfer & it is discharged from the other end.

GZG Series Tube Bundle Dryer (Pipe Bundle Dryer)is the indirect heated, contact type drying machine which can be both parallel flow and the counter-flow drying. Its major advantages are economic and practical. Among all kinds of the drying machines, it is the lowest in its power consumption and heat consumption. To evaporate one kg of water only consume 1.5 to 2 kg of steam, only 50% of the fluidizing dryer. To drying one ton of fermented grass powder consumes 15KW/H, only 25% compare to fluid-bed. Both the electric power consumption and the steam consumption reach the advanced level of the same kind products. The materials with high water content can be dried, the drying flexibility is wide. The drying time can be adjusted according to the materials property and moisture requirement. It can be continuous operation of high automation, or intermittent operation for special technical process. The machine has less accessories, parts occupy small area, has compact technical process and easy for installation.

Flow Chart

1 .The drying machine is suitable for drying the loose materials, such as: powder, particle and slice shape without big particles.

2. Application in chemical industry, food industry, feed industry and other industries, such as: starch factory, feed factory, meat processing factory, wine factory, beer factory and so on.

|

spec |

speed of rotation (rpm) |

main machine power (kw) |

heat exchange area (m2) |

drying capacity (evaporate kg of water/m2h) |

overall dimension (L*W*H)(mm) |

weight |

|

GZG50 |

5-8 |

5.5 |

50 |

4.7 |

8032×1712×2250 |

9.0 |

|

GZG100 |

5-8 |

7.5 |

100 |

4.7 |

9100×1912×2470 |

14.0 |

|

GZG150 |

5-8 |

11 |

150 |

4.7 |

8500×2212×2810 |

18.5 |

|

GZG200 |

5-8 |

11 |

200 |

4.7 |

10000×2212×2810 |

20.0 |

|

GZG250 |

5-8 |

15 |

250 |

4.7 |

10200×2212×2810 |

23.0 |

|

GZG300 |

5-8 |

22 |

300 |

4.7 |

10784×2488×3383 |

26.0 |

|

GZG350 |

5-8 |

30 |

350 |

4.7 |

12048×2488×3383 |

28.0 |

|

GZG400 |

5-8 |

30 |

400 |

4.7 |

13048×2488×3383 |

30.0 |

|

GZG500 |

5-8 |

45 |

500 |

4.7 |

11298×2982×3965 |

40.0 |

|

GZG600 |

5-8 |

75 |

600 |

4.7 |

12298×2982×4165 |

45.0 |

|

GZG700 |

5-8 |

75 |

700 |

4.7 |

13298×2982×4365 |

51.0 |

|

GZG800~G2000 |

5-8 |

75 |

700~2000 |

4.7 |

|

|

Features of material

|

normal material light industry |

water contents before the entering the machine |

water contents of dry product |

drying strength evaporation kgH2O/m2h |

energy consumption |

|

straw |

55% |

3-5% |

2.5-3 |

3500-3800 |

|

corn fibre |

60% |

10-12% |

4.8 |

|

|

fermented grass power |

45% |

12-13% |

4.7 |

|

|

wooden piece and wooden chip |

20% |

2-3% |

4.3 |

|

|

potato fibre |

65% |

10-12% |

4.8 |

|

|

distiller's grains for beer or spirit |

65 % |

10-12% |

4.9 |

|

|

feed carrier |

16% |

6-8% |

4.2 |

|

|

rape seed |

60% |

5-7% |

4.5 |

|

|

pig blood fermented power |

35% |

10% |

4.4 |

|

|

bone power |

40% |

10% |

4.6 |

-

GZG Series Tube Bundle Dryer (Pipe Bundle Dryer)

-

GZG Series Tube Bundle Dryer (Pipe Bundle Dryer)

-

GZG Series Tube Bundle Dryer (Pipe Bundle Dryer)

-

GZG Series Tube Bundle Dryer (Pipe Bundle Dryer)

- 2024-06-08 > Exhibition Invitation |ACHEMA 2024, Germany

- 2019-06-15 > P-MECH CHINA 2019 YIBU BOOTH NO: N3B10a

- 2019-04-15 > YIBU will attend the 57th CIPM Exhibition held in Changsha in Hunan province

- 2018-12-28 > Actived carbon particle mesh belt dryer made for Ingrevity

- 2018-03-10 > big spin flash dryer and spray dryer delivery to pakistan and Italy customer on time

- 2017-12-29 > two sets high speed centrifugal spray dryers and three sets of drum dryre delivered to Indonesia

- 2017-08-24 > one set of LPG-100 spray dryer is delivered to America

- 2017-08-24 > Five layers mesh belt dryer is sucessfully delivered to Manila(Philippines)

- 2017-04-05 > Exhibition interpack 2017 in Dusseldorf In Germany

- 2016-11-23 > The 18th International Exhibition in Moscow