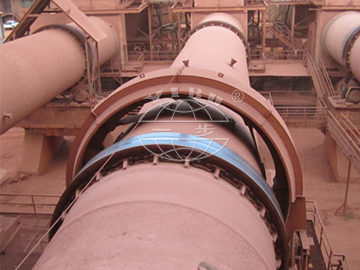

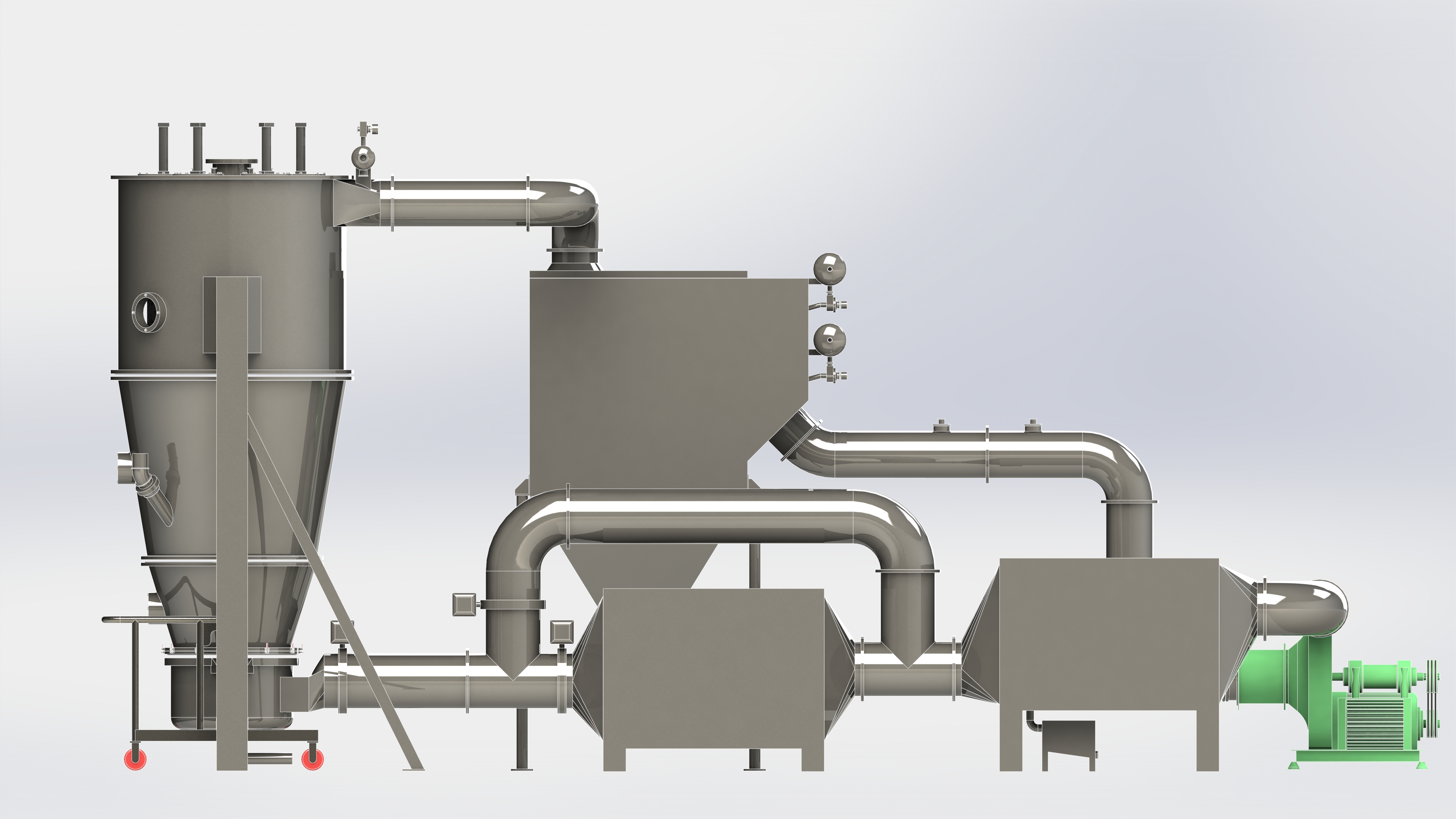

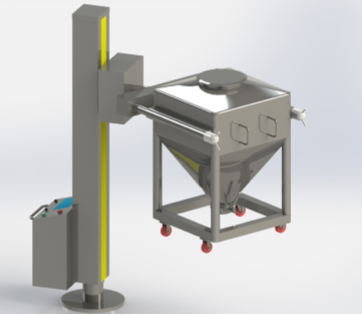

Urea Granulation Technology of Double Drums with a Fluidized Bed(13)

Source: | Date:

2011-04-26

| Hits:

Keywords:

11. Procedures for Technical Co-operation

*a) We Provide the Basic Information :

We will provide the basic information on DDG technology for customers

to understand what we can do.

*b) The Customers Registrations:

*(1) The brief introduction of the customers company:

We will provide a form for potential customers to fill in. The contents

of the form include the name of the urea plant, address, contact,

position of the contact person, tel., fax. Email, website, number of

employees, land area of the plant, registration time of the plant, time

of operation , fixed assets, total assets, yearly total business volume,

yearly profit, etc.

*(2) The Facility Briefing:

We will need to know the current situation of the existing facility,

including the design capability, raw materials, real production

volume of products, etc.

*(3) Engineering Plan:

The customers provide the time arrangement for granular remolding,

capability plan , targeted market, the engineering budget, etc.

*(4) Type of Purchasing:

We need to know if it is a contracted purchasing, bidding ,

non-formal bidding; or others.

*(5) The Technical Team:

*The customers provide to us its technical team, including its

engineers and technicians.

*c) The Customers Requirements:

We will conduct technical exchanges at the requirement of the customers.

*d) To Establish the Intention for Co-operation:

The customers have reached the basic intention for co-operation with us,

the two parties sign LOI and the Technical Confidentiality Agreement.

*e) Mutual Inspections:

The customers come to China for inspection of the technology, including

an on-the-spot investigation at the site of the urea plant remolded by the

DDG technology. Meanwhile, further technical exchanges are conducted

during the inspection time.

Meanwhile, we also send our group of specialists to the urea plant of the

customers for on-the-spot inspection as well as technical exchanges.

*f) Formal Signing of the Contract:

The customers and us formally sign the agreement for technical remolding

and services.

*g) Performance of the Contract:

The two parties perform the terms of the contract respectively. The

customers make the down payment to us, and we start the design for the

project and other preparations.

News

- 2024-06-08 > Exhibition Invitation |ACHEMA 2024, Germany

- 2019-06-15 > P-MECH CHINA 2019 YIBU BOOTH NO: N3B10a

- 2019-04-15 > YIBU will attend the 57th CIPM Exhibition held in Changsha in Hunan province

- 2018-12-28 > Actived carbon particle mesh belt dryer made for Ingrevity

- 2018-03-10 > big spin flash dryer and spray dryer delivery to pakistan and Italy customer on time

- 2017-12-29 > two sets high speed centrifugal spray dryers and three sets of drum dryre delivered to Indonesia

- 2017-08-24 > one set of LPG-100 spray dryer is delivered to America

- 2017-08-24 > Five layers mesh belt dryer is sucessfully delivered to Manila(Philippines)

- 2017-04-05 > Exhibition interpack 2017 in Dusseldorf In Germany

- 2016-11-23 > The 18th International Exhibition in Moscow

Products