METHOD OF AND MEANS FOR FLASH DRYING NATURALLY OCCURRING OILSEEDS

1.Method of seed preparation to control moisture and remove extraneous material which comprises producing down-flow, at a controlled rate, of a stream of seeds to be treated, producing an upward counterflow of air to carry out surface moisture and airborne extraneous material, moving said stream of seeds by a current of air through an enclosed flash dryer, said stream of seeds being under treatment in said dryer at a temperature of from 285° F. to 610° F. for a period of from 1 to 12 seconds, then subjecting said stream of heated seeds and carrying air to centrifugal separation of gases from seeds, and recovering said seeds.

2.Method of seed preparation to control moisture and remove extraneous material, which comprises moving a stream of the seeds to be treated downwardly through a tubular cleaning passageway, driving a stream of air upwardly through said passageway to clean the seeds, creating a stream of hot gases of combustion, conducting said stream of hot gases vertically through a tubular flash dryer and introducing said cleaned seeds into the stream of hot gases prior to the entry of said hot gases into the dryer and centrifugally separating the seeds from the hot gases.

3.Method of treating seeds to remove moisture and dirt which comprises subjecting a confined stream of downwardly flowing untreated seeds to an upward current of dry air to separate and remove moisture and dirt, creating a stream of hot gases, driving said stream of hot gases upwardly through a flash dryer, introducing said downwardly flowing stream of seeds into said last named stream of hot gases at a temperature of from 285° F. to 610° F. for a period of from 1 to 8 seconds subjecting said stream of gases and seeds to centrifugal separation and recovering said treated seeds.

4.The method of claim 3 wherein the stream of hot gases is the product of a gas burner and wherein a portion of the stream of heated gases, after separation from the seeds, is returned to said gas burner.

5.Method of treating seeds to remove extraneous solids and moisture which comprises setting up a downflowing stream of untreated seeds, driving a stream of heated air upward through said stream of seeds to remove moisture and extraneous solids, creating a stream of hot air and products of combustion at a temperature of from 285° F. to 610° F., delivering said stream of downflowing seeds after removal of moisture and external solids into an upwardly moving stream of hot air and products of combustion for a period of from 1.0 to 12.0 seconds and centrifugally separating the hot gases and treated seeds.

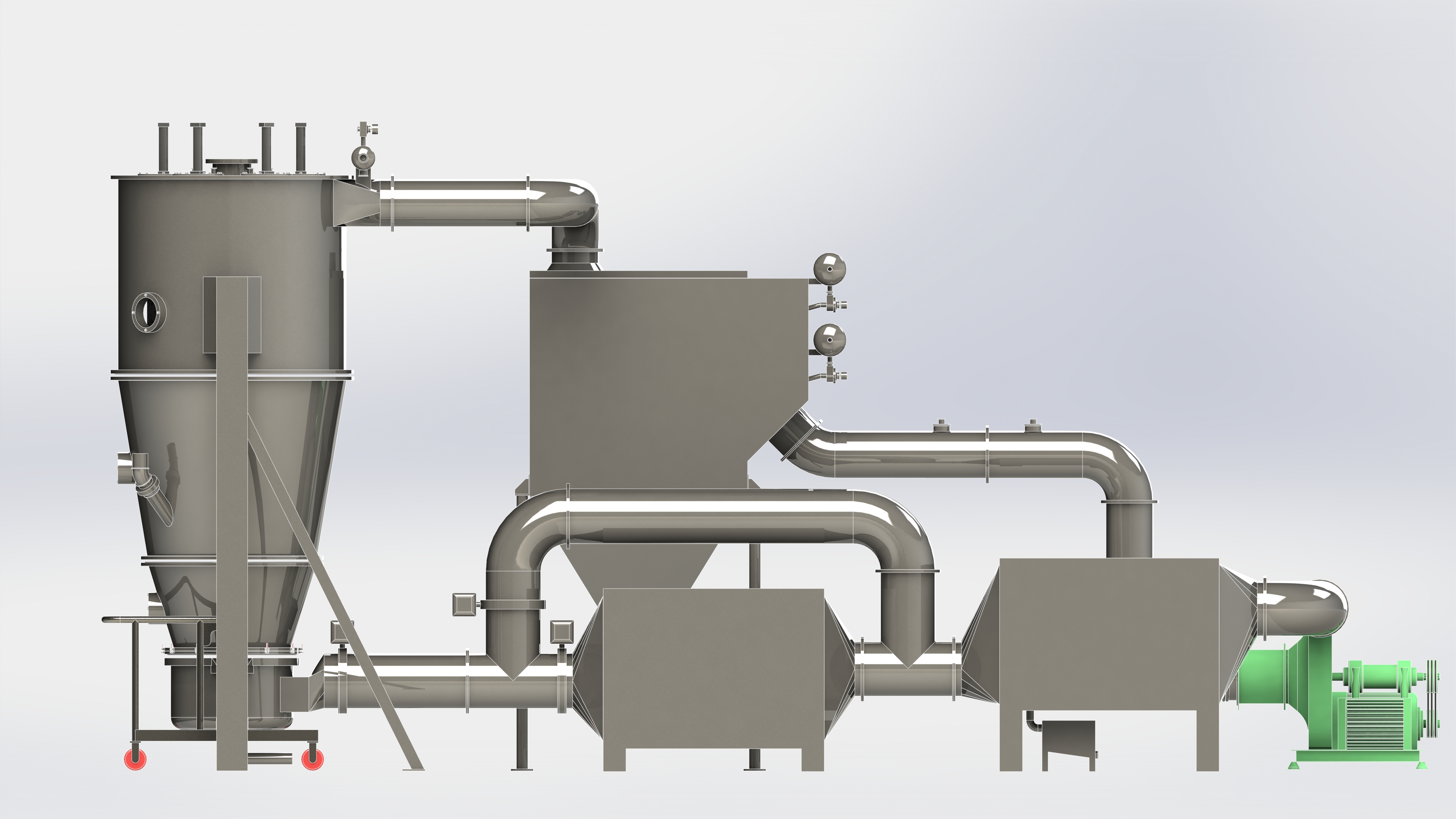

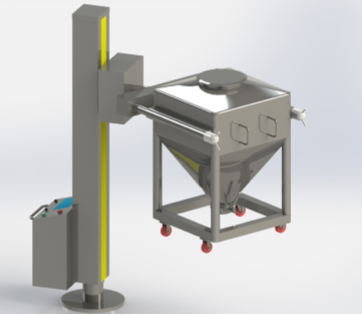

6.Means for cleaning and drying seeds comprising the combination of a countercurrent cleaning unit having a seed supplying inlet at its upper end and a seed outlet at its lower end, a hot air inlet adjacent its lower end and an exhaust air outlet at its upper end, a surge tank for seeds communicating with said lower end of the cleaning unit to receive discharge of seeds from said countercurrent cleaning unit, a hot air furnace, means for creating a flow of heated air from said furnace, a seed feeder for delivering seeds at a predetermined rate from the surge tank into said flow of heated air from said furnace, a flash dryer maintained at an internal temperature of 285° F. to 610° F., a cyclone separator, said flash dryer delivering the flow of heated air from the furnace and entrained seeds to the inlet of said cyclone separator, means for withdrawing the seeds from the separator and a pump having its inlet connected to the exhaust outlet of said separator and its discharge connected to the hot air inlet at the lower end of the countercurrent cleaning unit.

- 2024-06-08 > Exhibition Invitation |ACHEMA 2024, Germany

- 2019-06-15 > P-MECH CHINA 2019 YIBU BOOTH NO: N3B10a

- 2019-04-15 > YIBU will attend the 57th CIPM Exhibition held in Changsha in Hunan province

- 2018-12-28 > Actived carbon particle mesh belt dryer made for Ingrevity

- 2018-03-10 > big spin flash dryer and spray dryer delivery to pakistan and Italy customer on time

- 2017-12-29 > two sets high speed centrifugal spray dryers and three sets of drum dryre delivered to Indonesia

- 2017-08-24 > one set of LPG-100 spray dryer is delivered to America

- 2017-08-24 > Five layers mesh belt dryer is sucessfully delivered to Manila(Philippines)

- 2017-04-05 > Exhibition interpack 2017 in Dusseldorf In Germany

- 2016-11-23 > The 18th International Exhibition in Moscow