MOTIVATION FOR USE OF CONTROL IN INDUSTRIAL DRYING

Various formulations of the control problem

During drying the most important objective is to adjust some of the drying conditions while achieving the main final overall performances required.

-

Increase the yield while obtaining the specified final properties and desired quality of the dried products needed for their commerical use .This includes :size ,colour,visual appeal ,poprosity ,stability,texture ,stress resistance ,etc.Moreover ,one has to minimize the amount of off spec products induced bt changes in some of the drying conditions desired set -points (e.g.:the ambient mean humidity).

-

Decrease the cost of production dur to :the energy consumption,the manitenance cost and the drying time .Concerning the energy consumption,drying is highly energy-intensive opertion and it represents from 10%to 25% of the national indutrial energy in the developed world.Moreover it is also known that a majority of industrial dryers operate at low energy efficiency,from a disappointing 10% to a respectable 60%(this ratio is defined as the oretical energy required for the drying to the actual energy consumed).Therefore ,due to the escalating energy cost and more intensive global competition ,these performance have to be improved .This can be done using control tools

However ,in many situations ,the specified objectives are in conflict .For example ,improved properties and quality often demand to incrase the cost of production whereas decreasing the drying time may lead to decreas the quality .Therefore,adjusting the drying conditions is not straightforward and the objectives are often relaxed to botain manual drying control procedures .Such manual control procedures are the easiest to obtain but the drauback is the overall performance are not the best one could expect .So it is not a surprise that the deelopment of a "smart dryer "has recentlu emerged in drying technology .In the" smart dryer",a controller automatically tunes the drying conditions such that the expected ginak overall performances are reached .Such a "smart "attitude is quiet common in others industry (e.g.:chemical industry)since a few decades and in comparison ,relatively few works have been done until nowin control in drying technology

- 2024-06-08 > Exhibition Invitation |ACHEMA 2024, Germany

- 2019-06-15 > P-MECH CHINA 2019 YIBU BOOTH NO: N3B10a

- 2019-04-15 > YIBU will attend the 57th CIPM Exhibition held in Changsha in Hunan province

- 2018-12-28 > Actived carbon particle mesh belt dryer made for Ingrevity

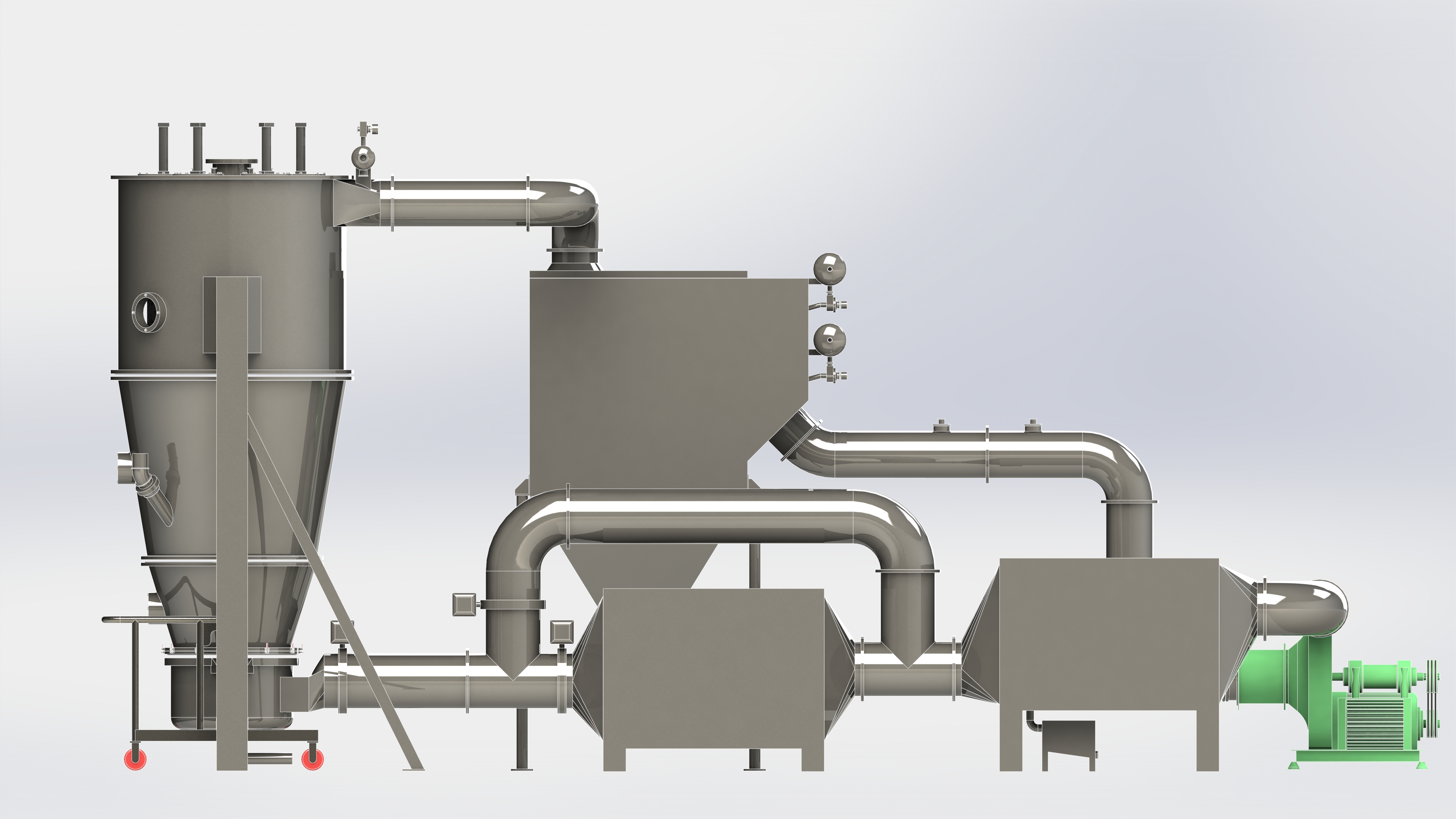

- 2018-03-10 > big spin flash dryer and spray dryer delivery to pakistan and Italy customer on time

- 2017-12-29 > two sets high speed centrifugal spray dryers and three sets of drum dryre delivered to Indonesia

- 2017-08-24 > one set of LPG-100 spray dryer is delivered to America

- 2017-08-24 > Five layers mesh belt dryer is sucessfully delivered to Manila(Philippines)

- 2017-04-05 > Exhibition interpack 2017 in Dusseldorf In Germany

- 2016-11-23 > The 18th International Exhibition in Moscow