Modelling spray drying processes for dairy products(15)

Conclusions

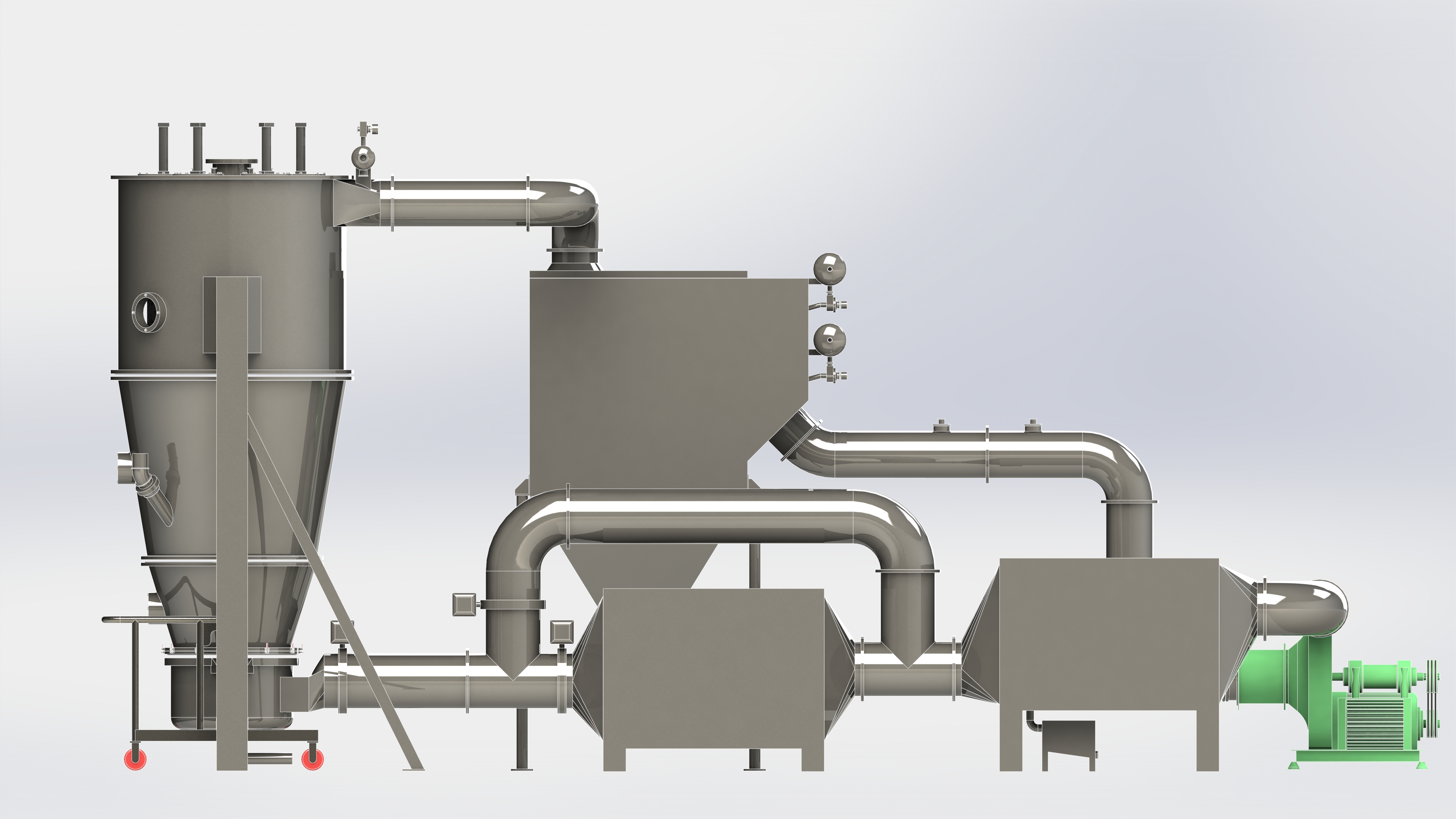

Predictive computer models have proven to effective in reducing processing consts and improving product quality in the food industry >These models also reduce the number of costly and time-consuming production trials needed for the development of new products or processes .Modelsare also successfully used for on-line control systems needed to maintain a constant product quality .The development of models for the food industry is an ongoing process.The integration of physico-chemical models ,computational fluid dynamics and control systems will enable an optimal use of availabe knowledge ,experimental data and comoputing speed .As a result ,it will soon be possible to predict more accurately the optimal process setings for the desired powder properties and to control the quality on-line.This will make it possible to adjust drying equipment quickly to newa products and will reduce variations in product properties to a large extent.

- 2024-06-08 > Exhibition Invitation |ACHEMA 2024, Germany

- 2019-06-15 > P-MECH CHINA 2019 YIBU BOOTH NO: N3B10a

- 2019-04-15 > YIBU will attend the 57th CIPM Exhibition held in Changsha in Hunan province

- 2018-12-28 > Actived carbon particle mesh belt dryer made for Ingrevity

- 2018-03-10 > big spin flash dryer and spray dryer delivery to pakistan and Italy customer on time

- 2017-12-29 > two sets high speed centrifugal spray dryers and three sets of drum dryre delivered to Indonesia

- 2017-08-24 > one set of LPG-100 spray dryer is delivered to America

- 2017-08-24 > Five layers mesh belt dryer is sucessfully delivered to Manila(Philippines)

- 2017-04-05 > Exhibition interpack 2017 in Dusseldorf In Germany

- 2016-11-23 > The 18th International Exhibition in Moscow