Modelling spray drying processes for dairy products(12)

Feed-forward control of evaporators and spray dryers

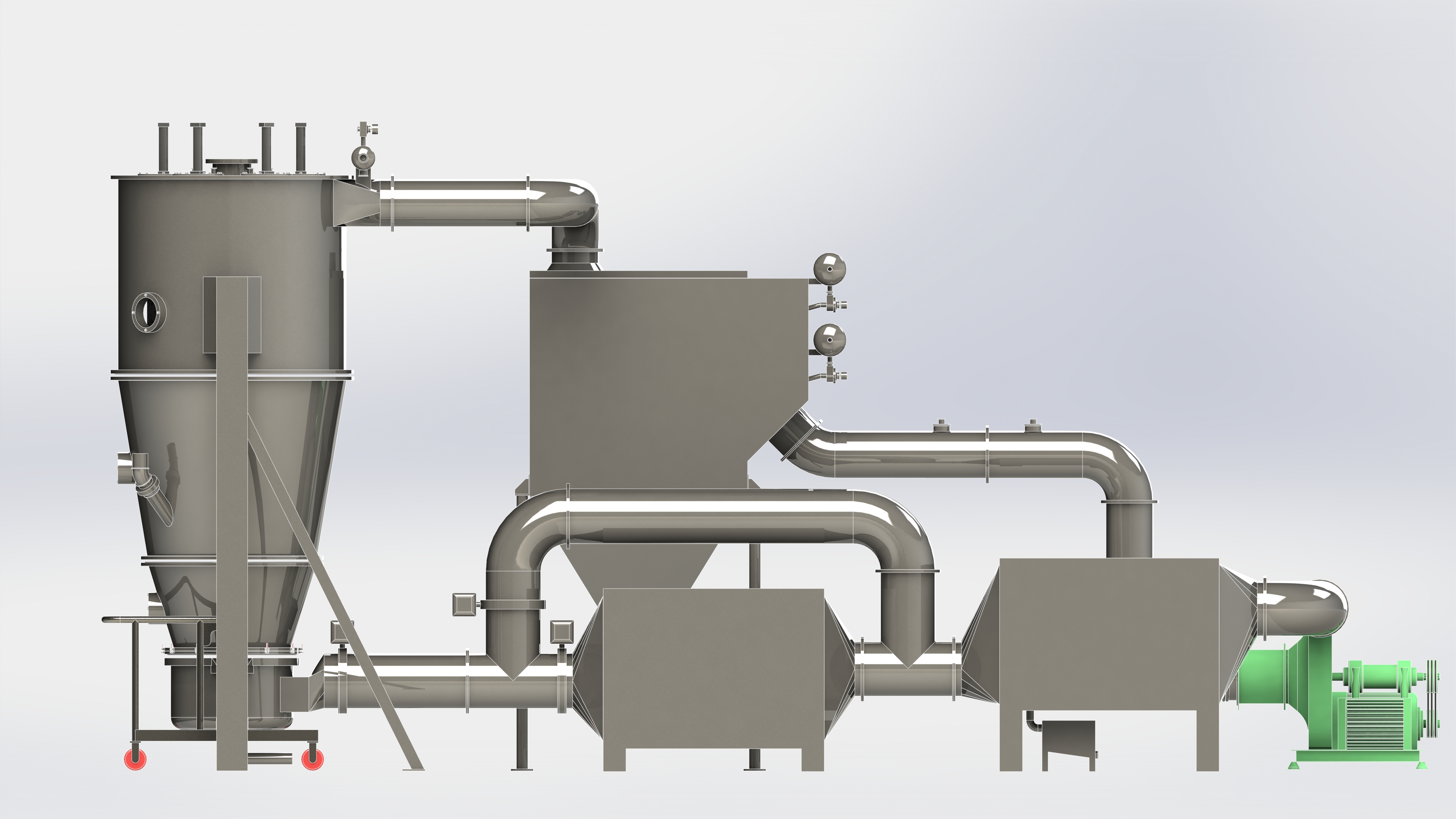

To obtain a high-quality powder, a constant dry matter content in the concentrate produced in the evaporator preceding the drying process is necessary .The occurrence of change s in the dry matter content in the feed to the dryer is one of the major sources of disturbance in the drying process .It is also advantageous to remove as much water as possible at the evaporation stage from an energy -savingpoint of view .In practice ,However due to variations that occur in drying matter content of the concentrate as a consequence of variations in feed and process variables the set-point for this dry matter content is often lower than is theoretically possible .This is in order to reduce the risk of too high a viscosity of the concentrate.Less variation in the dry matter content of the concenteate enables a higher set-point and thus also improves the energy efficiency of the powder production process ,When using conventional control technology ,such as single -loop proportional integral derivative.controllers,the long time delay from input to out put will result in a relatively long period of off-spec concentrate,Modern design methods for multivariable control make it possible to design compensators that reduce or eliminate the off-spec period ,For the design of such a multivariable control system one should determine the dynamic dehaviur of the evaporator involved. This can be done either by using a physiacal model simulating the dynamic behaviour ,or by carrying out step-response measurements on the actual evaporator and using system identification techniques to draw up a black boxmodel.The first approach is more flexible and robust for handling changes in the design and process operation .The advantage of the latter approach is that it requires less detailed knowledge ablout the design of the evaporator .Also in drying process there is trend of using more and more predictive models in the control strategy.The nain issue for the automatic control of spray dryrs is to achieve a reduced variation in the moisture content of the powder enablinga higher set-point for the moisture content ,which greatly reduces the operating costs.

- 2024-06-08 > Exhibition Invitation |ACHEMA 2024, Germany

- 2019-06-15 > P-MECH CHINA 2019 YIBU BOOTH NO: N3B10a

- 2019-04-15 > YIBU will attend the 57th CIPM Exhibition held in Changsha in Hunan province

- 2018-12-28 > Actived carbon particle mesh belt dryer made for Ingrevity

- 2018-03-10 > big spin flash dryer and spray dryer delivery to pakistan and Italy customer on time

- 2017-12-29 > two sets high speed centrifugal spray dryers and three sets of drum dryre delivered to Indonesia

- 2017-08-24 > one set of LPG-100 spray dryer is delivered to America

- 2017-08-24 > Five layers mesh belt dryer is sucessfully delivered to Manila(Philippines)

- 2017-04-05 > Exhibition interpack 2017 in Dusseldorf In Germany

- 2016-11-23 > The 18th International Exhibition in Moscow