Mo delling spray drying process for dairy products(7)

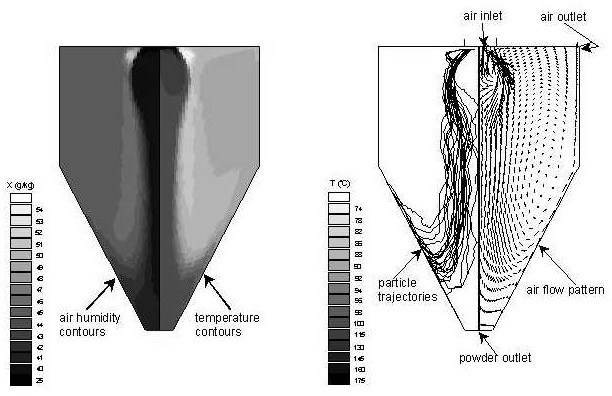

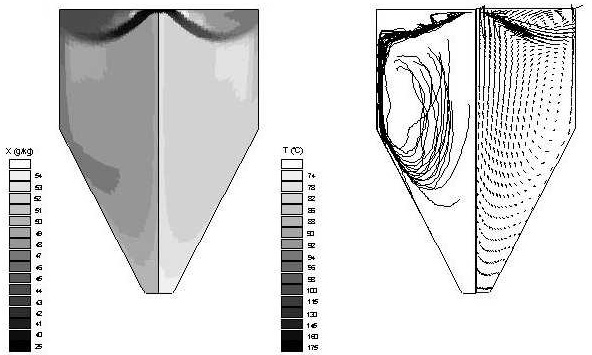

Figure 3 shows the temperature and air humidity in the dryer sa contours (Fig.3a) and the simulated flow pattern of the air and particle trajectories(Fig.sb). When the rotary speed of the atomiser is low ,droplets leave the atomiser with an average velocity of 58m.s1. The air inlet is placed at the centre of the ceiling and the inlet air-flow is directed straight downwards .Inthe dryer there is a main circulation air-flow , which is downwards at the centre axis and upwards at the outer side .A part of the air-flow leaves the dryer at the outlet ,which is positioned at the upper siade of the culindrical chamber ; a smaller part of the air-flow recirulates towards the air inlet .The air that reaches the outlet is cooled to about 90℃ due to evaporation of water .Over the years ,the capapcity of the dryer and the rotary-speed of the atomiser have been gradually increased .In this dryer , the momentum exchange from the atomised spray-droplets to the air has a strong influence on the flow pattern,as is shown in Figure 4.The figure shows the result of a simulation with a higher rotery speed (droplet velocity 150 m.s1).The main air-flow has reversed compared to Figure 3 and there is acirculation of hot air in the upper part of the dryer .The temperature of the outlet air is now much higher (Fig.4a). This simulation shows that the operators idea was correct:at a high rotary speed .reversal of the main air-flow and a short cut of hot air from inlet to outlet may be expected .The dryer concerned has now been reconstructed for high-pressure nozzle atomisation.

Figure3.Computational(NIZO Dry-Sim) of an industrual spray dryer. Initial droplet velocity :58 m.s:(a) air humidity and temperature contours ; (b)simulated air-flow patterns and particle trajectories.

Figure 4.Computational simulation (NIZO Dry-Sim) of an industrial spray dryer . Initial droplet velocity:15m.s 1:(a)air humidity and temperature contours; (b)simulated air-flow patterns and particle trajectories.

- 2024-06-08 > Exhibition Invitation |ACHEMA 2024, Germany

- 2019-06-15 > P-MECH CHINA 2019 YIBU BOOTH NO: N3B10a

- 2019-04-15 > YIBU will attend the 57th CIPM Exhibition held in Changsha in Hunan province

- 2018-12-28 > Actived carbon particle mesh belt dryer made for Ingrevity

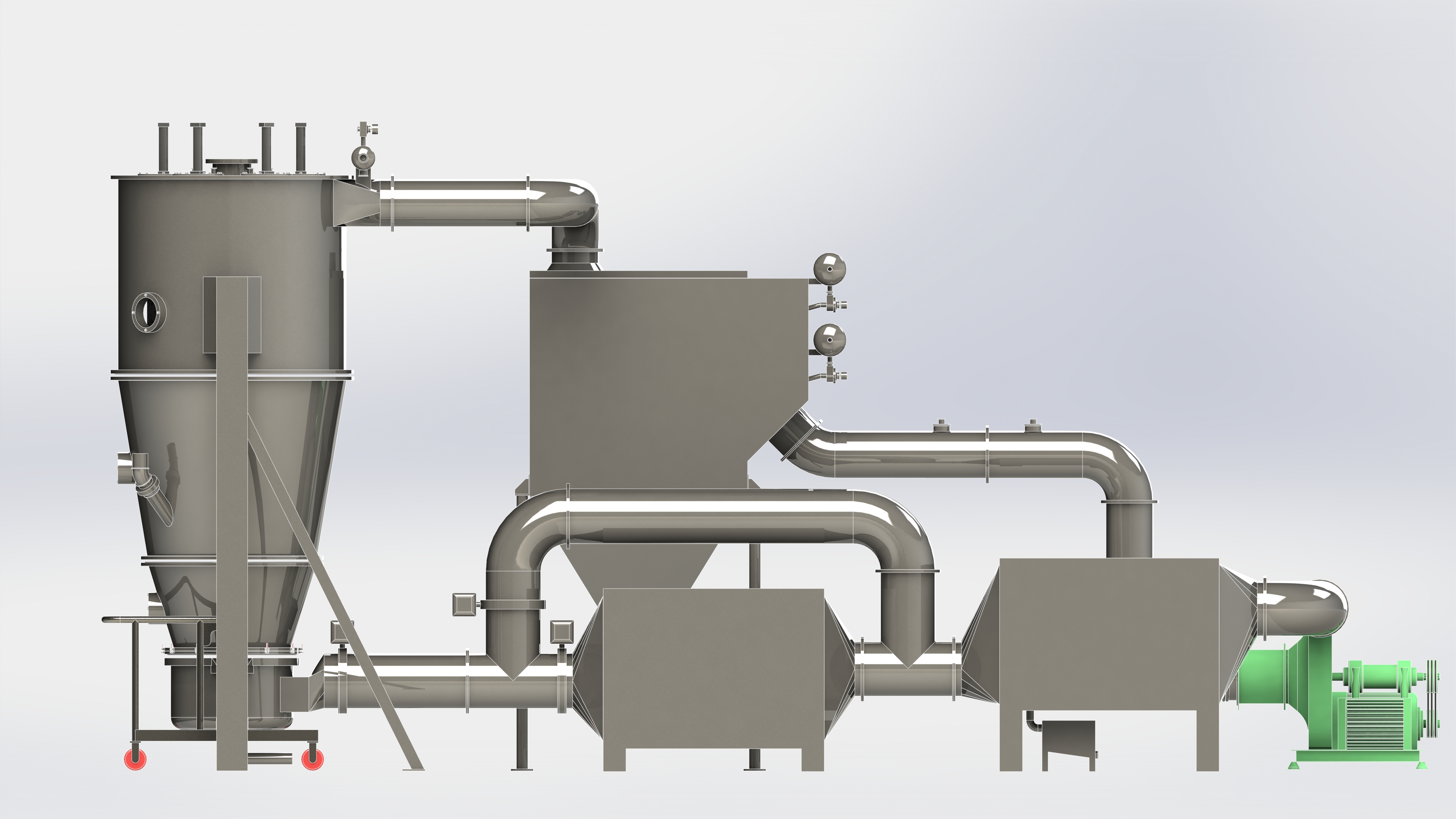

- 2018-03-10 > big spin flash dryer and spray dryer delivery to pakistan and Italy customer on time

- 2017-12-29 > two sets high speed centrifugal spray dryers and three sets of drum dryre delivered to Indonesia

- 2017-08-24 > one set of LPG-100 spray dryer is delivered to America

- 2017-08-24 > Five layers mesh belt dryer is sucessfully delivered to Manila(Philippines)

- 2017-04-05 > Exhibition interpack 2017 in Dusseldorf In Germany

- 2016-11-23 > The 18th International Exhibition in Moscow