MOdelling spray drying process for dairy products(5)

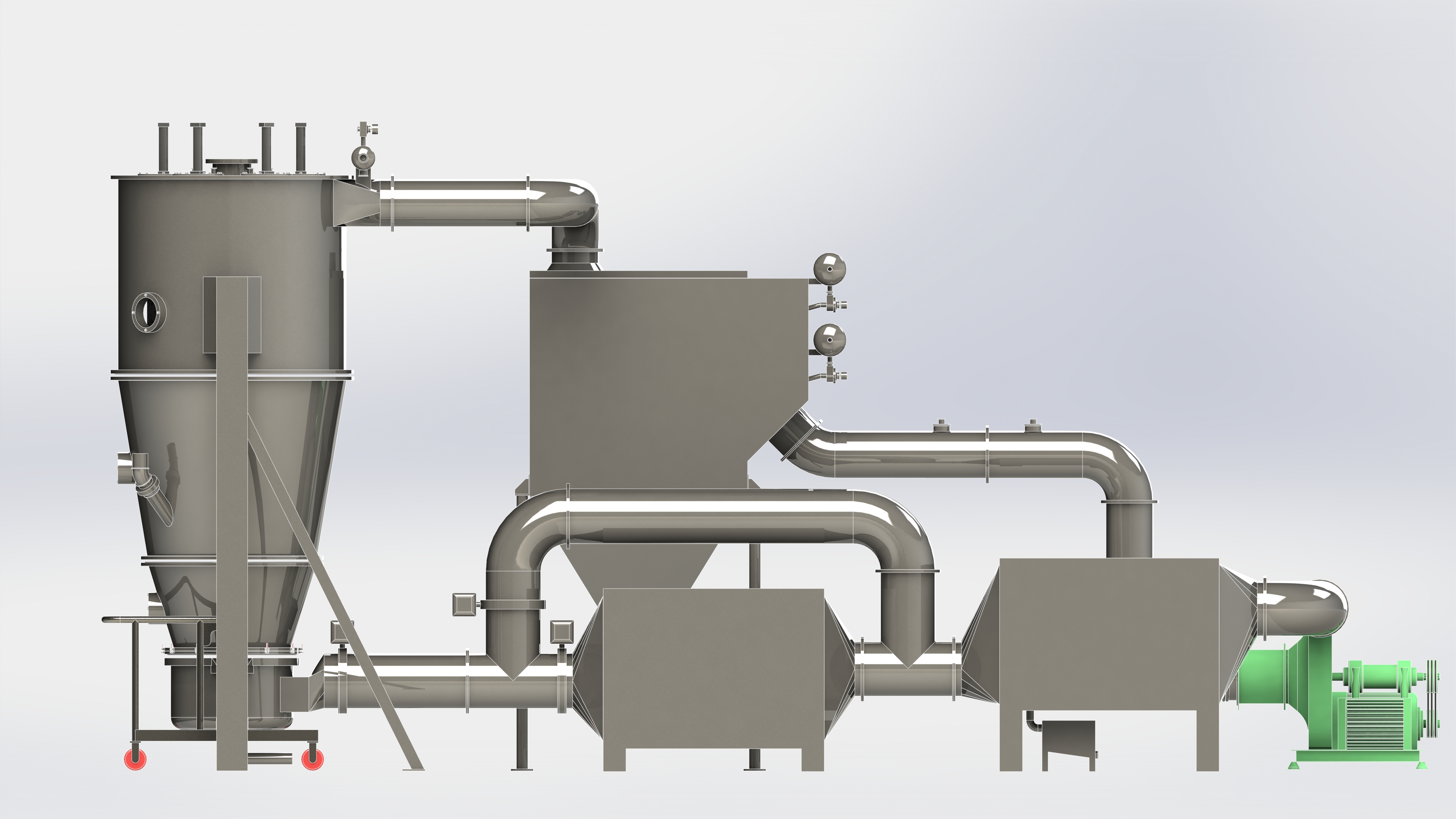

Simulation of flow patterns local drying behaviour, fouling of spray dryers and insolubility index:Drysim

In order to simulate the drying process in more detail , It is necessary to gain insight into the flow patten ,local temperature and local moisture content of the air and the temperature-time history of drying particles.The flow paten of air depends on the geometry of the dryer and the location and design of the air inlet and air outlet channels . The trajectories followed by the (drying) particles depeng not only on the air-flow pattern but also on the position and method of atomisation. At NIZO food research the drying model DrySim was developed as a tailor-made simulation program for spray dryers ,making use of computational fluid dynamics (CFD techniques. DrySim is a two-dimensional simulation model of a spray deryer .it calculates the flow pattern ,temperautre and moisture content of air , the trajectories of the atomised particles and the drying behaviour of individual particles .The gas-flow is described by the time-averaged Navier Stokes equations in combination with the standard k-ε turbulence model. Source terms account for the effect of the droplet on the flow .A particle tracher, based on the equation of motion ,is used to simulated the particle trajectoried .Since the particles affect the gas -flow (and vice versa),an iteration procedure is used to solve the equatiopns (see Fig.2). The drying of froplets is influenced(from particle surface to surrounding air) and internal transport phenomna (fdiffusion of water within particles ). The differential equation that describes the diffusion prces of spherical particles is solved numerically , simultaneously with the equations for external heat and mass transfer .In order to obtain reliable results ,it takes several hours using a personal conputer(800MHz,128Mb Ram) to carry out one simulation.

Figure 2. NIZO DrySim cakculation flowchart

- 2024-06-08 > Exhibition Invitation |ACHEMA 2024, Germany

- 2019-06-15 > P-MECH CHINA 2019 YIBU BOOTH NO: N3B10a

- 2019-04-15 > YIBU will attend the 57th CIPM Exhibition held in Changsha in Hunan province

- 2018-12-28 > Actived carbon particle mesh belt dryer made for Ingrevity

- 2018-03-10 > big spin flash dryer and spray dryer delivery to pakistan and Italy customer on time

- 2017-12-29 > two sets high speed centrifugal spray dryers and three sets of drum dryre delivered to Indonesia

- 2017-08-24 > one set of LPG-100 spray dryer is delivered to America

- 2017-08-24 > Five layers mesh belt dryer is sucessfully delivered to Manila(Philippines)

- 2017-04-05 > Exhibition interpack 2017 in Dusseldorf In Germany

- 2016-11-23 > The 18th International Exhibition in Moscow