MOdelling spray drying process for dairy products(3)

Relation between the process conditions of the spray drying process, energy consumption and powder properties: DrySPEC2

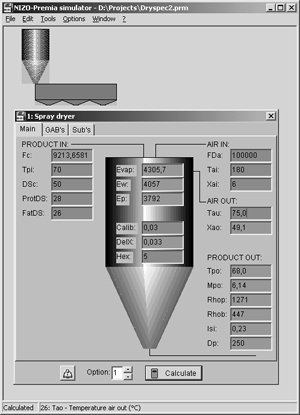

The first drying model that was developed by NIZO food research is DrySPEX2(Dryer system for property and Energy Control).This computer model describes the relations of the drying process ,energy consumption and the properties of the powder produced for a two-stage dryer . The purpose of this model is to establish the process conditions that ensure optimal exploitation of the capabilities of exiting drying installations with regard to energy consumption and the powder properties .This model assumes a near-equilibrium state of water vapour pressure between powder and outlet air which eliminates the need for a detailed description of heat and mass transfer phenomena during the driving process .In Figure 1 a screenshot of DrySPEC2 is shown .The model is integrated in a user-friendly interface in which other software modules can also be accessed.

Figure 1. Screenshot of NIZO DrySPEC 2 with user-friendly interface

- 2024-06-08 > Exhibition Invitation |ACHEMA 2024, Germany

- 2019-06-15 > P-MECH CHINA 2019 YIBU BOOTH NO: N3B10a

- 2019-04-15 > YIBU will attend the 57th CIPM Exhibition held in Changsha in Hunan province

- 2018-12-28 > Actived carbon particle mesh belt dryer made for Ingrevity

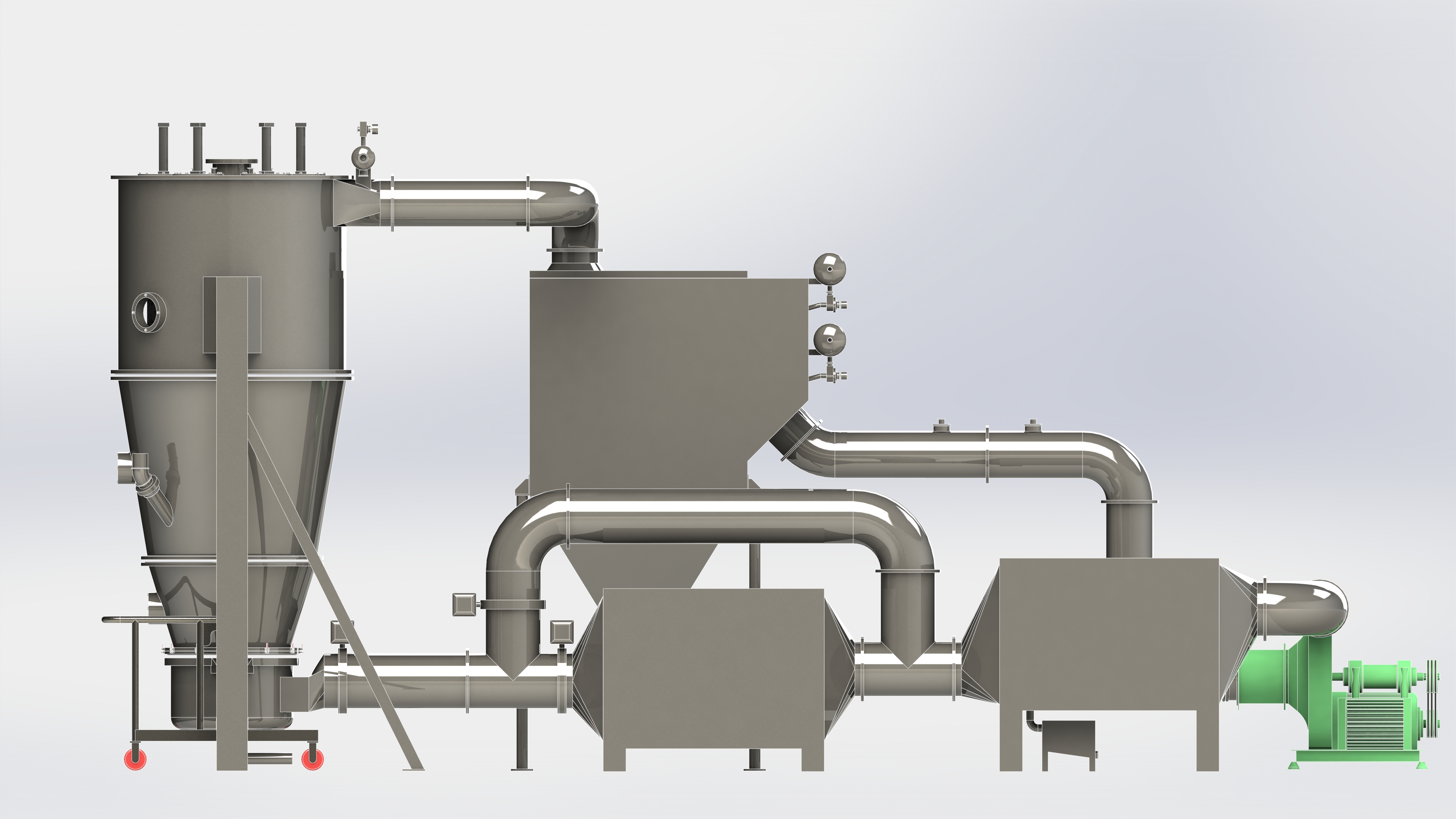

- 2018-03-10 > big spin flash dryer and spray dryer delivery to pakistan and Italy customer on time

- 2017-12-29 > two sets high speed centrifugal spray dryers and three sets of drum dryre delivered to Indonesia

- 2017-08-24 > one set of LPG-100 spray dryer is delivered to America

- 2017-08-24 > Five layers mesh belt dryer is sucessfully delivered to Manila(Philippines)

- 2017-04-05 > Exhibition interpack 2017 in Dusseldorf In Germany

- 2016-11-23 > The 18th International Exhibition in Moscow