Choosing of the pharmaceutical line, the principle of dryer

Source: | Date:

2010-10-26

| Hits:

Keywords:

1 Vacuum Oven

Vacuum drying oven to a more ancient device, inside is heated plate divided into several layers. Heating plate which leads to hot water or low pressure steam as the heating medium, the shop is expected to be dry and drugs on the heating plate board, close the door the box with the vacuum pump into a vacuum. Heating plate in the heating medium circulation will be heated to specified temperatures medicines, water began to evaporate, and with the gradual vacuum pumped. This device is easy to control, can be recovered by evaporation of the solvent condensation, drying process, drugs can not easily be contaminated, can be used in pharmaceutical dry, package materials and heat treatment on sterilization. In the last century, more than 80 years with the bulk drugs industry, the equipment as the main dryer, but because of the feed tray for easy cleaning on-line and on-line sterilization, drying slowly, workers, labor-intensive, but also to achieve the drug homogeneity, even after drying The mixed powder mixing device is now API has been very little large-scale production applications, used for medium and small pilot production or package material heat treatment.

2 Vacuum rotary dryer

Vacuum rotary dryer from the double cone blender, multi-device for the cylindrical body, tapered at both ends, also commonly known as the biconical dryer. There are two hollow cone hanging central axis for rotation support and vacuum equipment, hot water channel. Drugs in the dryer while drying side rotation, the entire batch of drugs to ensure a good homogeneity. Heat medium from one end of the hollow tube into the jacket, inside the heat with the other side of the hollow tube in the exhaust pipe emissions, and recovery of volatile solvents by condensation. This device is in the last century, 80 years developed by the Shanghai Institute of Pharmaceutical Industry, in my company's successful trial production of penicillin and antibiotics, the industry will soon be replicated across the country, many domestic manufacturers. Later, there uniaxial multi-dimensional rotary dryer rotary dryers, tilt-type rotary dryer and the like. This device is equipped with supporting vacuum system, solvent recovery systems, cleaning sterilization systems. Since this equipment is simple and easy to adjust batch production can be carried out cleaning on-line and on-line sterilization, thereby becoming small and medium sized enterprises antibiotic drug of choice for raw material dryer, such as penicillin, lincomycin, chlortetracycline, caffeine, etc. can be selected. Equipment selection, the main consideration of the concentricity of two hollow shaft and hollow shaft sealing problems in order to ensure the smooth operation of equipment, concentricity requirement shaft runout is less than 0.01mm, the main effect of the hollow shaft seal is to prevent pollution of lubricants or fillers drugs.

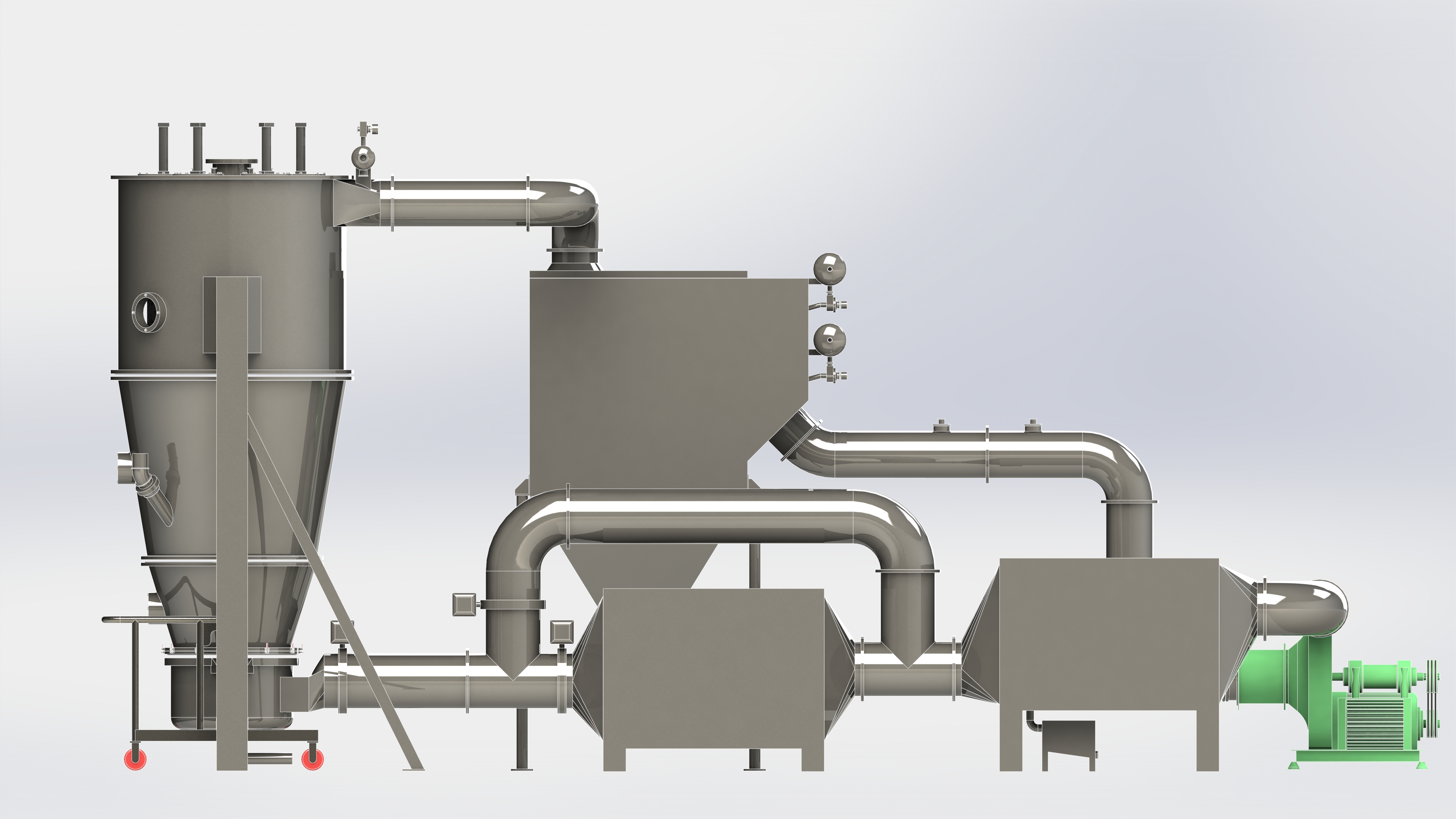

3 Air Dryers

Air dry for easy dehydrated particles, powder-like materials, can quickly remove the material water (mainly surface water). In air drying, due to material in the dryer to stay a short time, so get the best quality of dried product control. Wet material through the feeder with hot air fully mixed in the dry wind to attract the same time, into the drying tube is dried further. The wind can not attract particles in the dryer wet weight continue to be hit, broken, dry, until it can be played well into the dry air suction pipe, dry end of the cyclone tube. This device is mainly used in the pharmaceutical industry, and some health care products oxytetracycline production.

4 Spray Dryer

This device is similar to air dry the drying process. After the initial filtration of air heated by the heater to produce hot air by a number of class filtering (according to pharmaceutical grade optional), and then in the drying room at the top of volute channel distributor hot air generated by the uniform rotation of air into the drying chamber. Materials are filtered through the centrifugal disc atomization or pressure nozzles, resulting in scattered, fine materials fog, fog and the swirl of hot material exposed to the air, the moisture rapidly evaporating, in a very short period of time materials are dry. This device is suitable for solution, emulsion, suspension liquid, paste, liquid and other liquid materials and good mobility dry, my company 50 years from the 20th century to the present has been using such equipment streptomycin, and now trades as the raw material medicine streptomycin, gentamicin, and various bio-dried extract of the device can be selected.

5 FBC

This device is found drugs from the Ministry of bed to join, hot air blowing from the bottom, and through the porous plate and the distribution of a certain material thickness of the material contact, the material was fluid, boiling point, flipping up and down in the air flow, mixing and collide with each other, gas solid contact between the large area to carry out intense heat and mass transfer, the larger increase of the drying rate and drying efficiency, is an ideal drying equipment. Some of the more wet and dry materials can be an indicator of water meet the requirements. Fluid boiling thermal efficiency. Residence time can be adjusted, easy to get low-moisture product. Size of the particles in the bed surface available grade, coarse-grain can be discharged from the bed, fine powder discharged from the dust collector. Some materials, bag dust removal can be done within the host (built-in), save area, simple structure, low investment. This device is suitable for powder, granules, and wire, strip drying materials, equipment, fully enclosed, you can conduct online cleaning and sterilization, in the pharmaceutical industry, the production of antibiotics and the application of semi-and Anti-wide.

6 Bed

This device has bed and vibration fluidized bed drying by the liquidity impact of drug use most of vibrated fluidized bed. Dryer exciting force generated by the vibrating motor to make the machine vibration, the material in a given direction under the action of the exciting force leap forward at the same time enter the hot bed of materials in a fluid state, the material particles and hot air full access to carry out violent mass Heat and mass transfer process, this time the highest thermal efficiency. On the negative pressure chamber at the micro-state, moist air from the suction fan leads, dry material discharged from the discharge port to achieve the desired drying effect. This device is streaming uniform, no dead ends, uniform temperature distribution and thermal efficiency. Applies to particles, powder, strip, wire-like materials, dry stems, such as starch, glucose, and many high-volume production of pharmaceutical intermediates can be selected.

7 Freeze Dryer

Vacuum freeze-drying machine for heat-sensitive or easily oxidized drugs, dry, commonly known as freeze dryers, mainly including freeze-dried case, vacuum system, heating system, cooling system. By shelf space can be divided into small-scale pilot freeze dryer, medium-sized production freeze dryers, large-scale industrial production freeze dryers. Bulk drugs and formulations of drugs are a lot of dry application of freeze dryers. Main demands of its high reliability, sterilization fully functional, the same shelf and board within the temperature difference between layers is not greater than 1.5 ℃, which also must demand better flatness shelf. This device is used when the dry bulk drugs in order to ensure uniformity of products, the best increase in powder mixing device. Ampicillin, a large number of blood products, artificial cultivation of drugs, antibodies, vaccines are largely selected freeze dryer.

The past 20 years with the reform and opening up the process of rapid development of the pharmaceutical industry, while the flourishing drug machine industry also show an excellent situation, the author had the honor because of his work in several of the above drying device has been applied experience, because there are a lot of insight limited Good dryer is not introduced into, such as tray dryer, spouted bed dryers, flash dryers, microwave, dryer, etc. series. Dryer according to drug use when the characteristics of finished products to achieve the ideal state may be, in particular, to consider the sterile bulk drugs and sterile drying equipment to ensure the material. Pharmaceutical drying equipment in China has developed very rapidly in the Jiangsu area, professional drying equipment factory is very large, both interoperability of their products, but also have different features, which is used for dry bulk drugs imported equipment at home, and to choose "Drug Production Practice "(GMP) provides the conditions for the ideal dryer.

News

- 2024-06-08 > Exhibition Invitation |ACHEMA 2024, Germany

- 2019-06-15 > P-MECH CHINA 2019 YIBU BOOTH NO: N3B10a

- 2019-04-15 > YIBU will attend the 57th CIPM Exhibition held in Changsha in Hunan province

- 2018-12-28 > Actived carbon particle mesh belt dryer made for Ingrevity

- 2018-03-10 > big spin flash dryer and spray dryer delivery to pakistan and Italy customer on time

- 2017-12-29 > two sets high speed centrifugal spray dryers and three sets of drum dryre delivered to Indonesia

- 2017-08-24 > one set of LPG-100 spray dryer is delivered to America

- 2017-08-24 > Five layers mesh belt dryer is sucessfully delivered to Manila(Philippines)

- 2017-04-05 > Exhibition interpack 2017 in Dusseldorf In Germany

- 2016-11-23 > The 18th International Exhibition in Moscow

Products