Due diligence for energy-saving

Source: | Date:

2010-09-06

| Hits:

Keywords:

Changzhou Yibu Drying Equipment Co.,Ltd.

General Mamager: Guocai Zha

The so-called low-carbon economy refers to an economic model based on the low power consumption, low pollution, and low emission, the essence thereof is the efficient use of energy and the development of clean energy. In this sense, it seems that low-carbon economy has nothing to do with the drying equipment as a productive tool, but that is not the case. In industrial production, a low-carbon economy depends on energy technology and innovative emission reduction technology. The application of energy saving technologies and equipment is an irresistible general trend. As to the drying industry, it confronts both opportunities and challenges.

Development opportunities for low-carbon economy

In China, consumption VAT as a representative for tax reform as well as a series of implementation of industrial transformation policy bring about new development opportunities for the drying equipment industry. Our country’s acceleration of the industrialization process will be conducive to keeping the equipment manufacturing industry including the drying machinery for a long and vigorous time.

At present, many chemical, food and pharmaceutical companies still use the production mode at the lower cost and lack the advanced processing equipment. In the short term, those companies seem to make a small investment, but the long time low production efficiency will lead to high energy consumption and high pollution, and thus apparently go against the low-carbon economy we advocate currently.

More and more chemicals, food and pharmaceutical companies will spend more money on production facilities so as to create a more high-end production platform, conserve resources, improve efficiency and make a transition to low carbon economy. The development spring will witness those manufactures that produce the energy-efficient facilities.

A bright prospect for energy-efficient equipment

This year’s NPC &CPPCC advanced a high requirement of lowering energy consumption, and thus will put forward a new requirement of energy conservation index for drying equipment. A great effort has been made in the aspects of the application of new technologies, energy conservation, etc. by Changzhou Yibu long before. The new technologies bring about the consumption-saving of direct steam, the recuperation of secondary energy in the process of availability, the reduction of emission of three wastes through the market research and drawing on the proven technology concerned both at home and abroad. Some related applied processes and construction have been introduced to the course of the design and manufacturing of products, which will unceasingly improve the technology level of equipments and fit for the demand of markets. The following tasks we done are as follows:

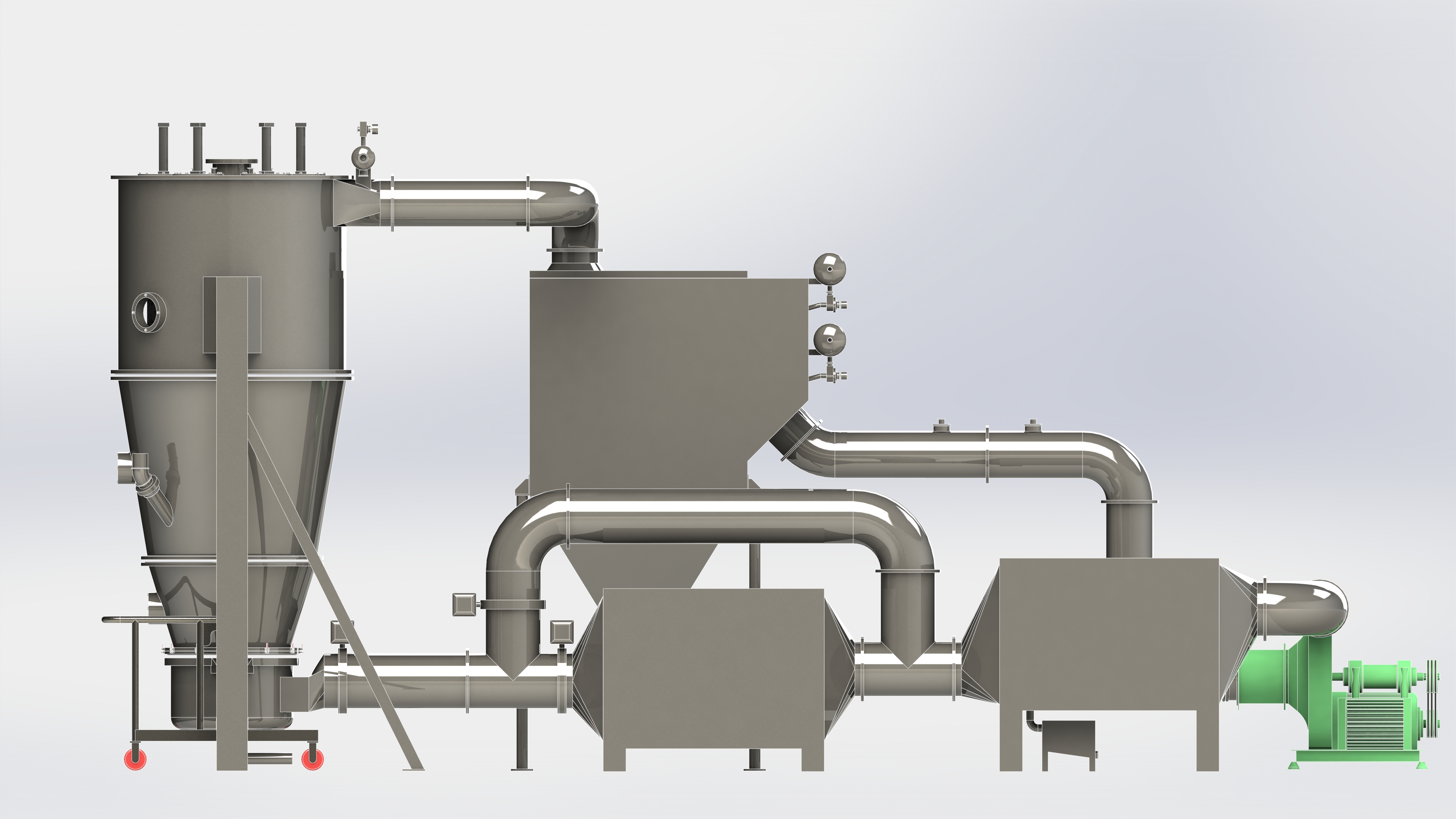

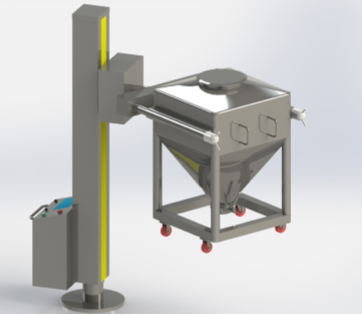

Firstly, as for the closed loop centrifugal spraying drying system developed by our company for the production of activator, we change its primary process conditions. Instead, we use spraying drying technology to reduce the intermediate links and reach the requirement of environmental protection. In the meantime, this equipment also adopts the spray and solvent recovery technology to improve the material yield and the solvent recovery can also be recycled as well. And then, Our company firstly puts the index of the energy consumption and the requirement of waste gas emission into the standard, which is regarded as the index of exfactory inspection when formulating the standard of spray dryer for Chinese traditional medicine extract.

Secondly, some multiple function equipments such as granulating-drying, drying-filtering, spraying- microwave, belt-microwave, etc. just taking spraying- microwave as an example, in the earlier stage, the spray hot air convection drying can be adopted to decrease the cost and reach the drying effect as expected; in the later stage, the microwave drying can be adopted to increase the drying velocity and lower the energy consumption on the basis of guaranteeing the drying effect.

Independent innovation based on the responsibility for environmental protection

The drying equipment itself with so small energy consumption can produce a great many products, so the drying equipment manufacturers in addition to reducing the resource consumption and pollution in the process of production should take the responsibility of environment-friendly products of low energy consumption, the equipments of integrated utilization of resources and the equipments of recycling and reuse as well as the advanced technology of manufacturing and processing in an effort to improve the efficiency of equipment manufacturing.

Low carbon should be not just a fashion but a responsibility and a strategy. We suggest that the drying equipment companies focus on the energy-saving and unceasingly enhance innovative ability and the level of the products and technologies in order to contribute to the low carbon economy and the reduction of energy consumption.

News

- 2024-06-08 > Exhibition Invitation |ACHEMA 2024, Germany

- 2019-06-15 > P-MECH CHINA 2019 YIBU BOOTH NO: N3B10a

- 2019-04-15 > YIBU will attend the 57th CIPM Exhibition held in Changsha in Hunan province

- 2018-12-28 > Actived carbon particle mesh belt dryer made for Ingrevity

- 2018-03-10 > big spin flash dryer and spray dryer delivery to pakistan and Italy customer on time

- 2017-12-29 > two sets high speed centrifugal spray dryers and three sets of drum dryre delivered to Indonesia

- 2017-08-24 > one set of LPG-100 spray dryer is delivered to America

- 2017-08-24 > Five layers mesh belt dryer is sucessfully delivered to Manila(Philippines)

- 2017-04-05 > Exhibition interpack 2017 in Dusseldorf In Germany

- 2016-11-23 > The 18th International Exhibition in Moscow

Products